Active Carbon Knowledge

Activated Carbon Filter: Production and Function

Activated carbon production

Activated carbon can be obtained from various materials such as hard coal (anthracite coal), coconut shells, brown coal, and wood. For cost reasons, activated carbon is usually manufactured using the steam activation process. During this process, the raw material is activated by hot steam under vacuum in a furnace at a temperature of approximately 900 to 1100 °C. The absence of oxygen prevents the material from burning. Instead, the heat causes the internal surface of the material to increase significantly. Activated carbon produced in this way can then be further processed for various purposes.

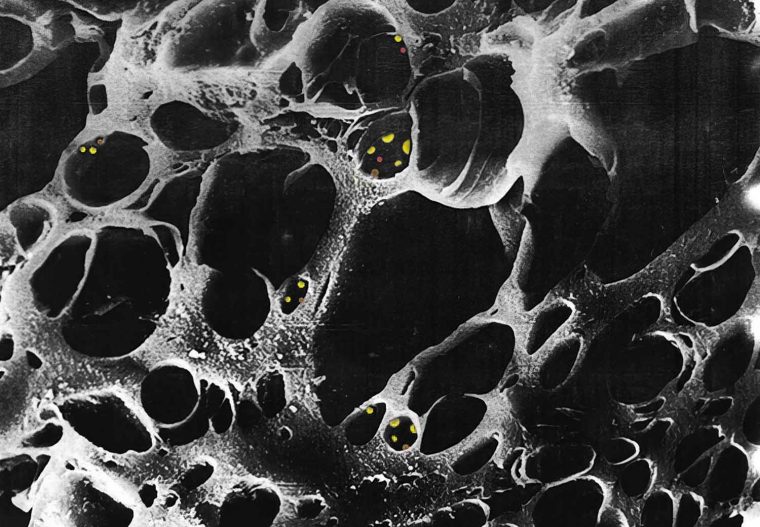

Detail of the internal structure of activated carbon. Odour molecules are trapped in activated carbon.

How does the activated carbon filter work?

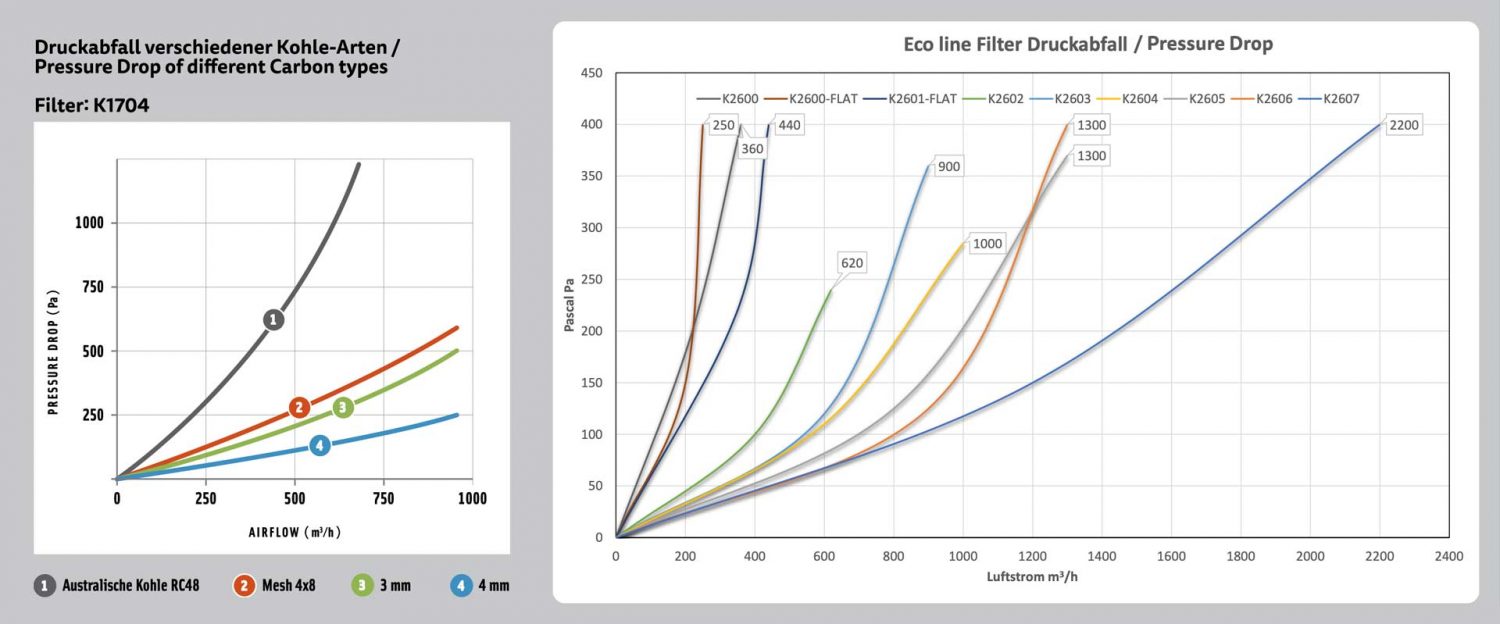

Depending on the carbon type used, the activated carbon filter has certain adsorption properties. Once air starts flowing through the carbon filter, odour molecules are trapped inside the activated carbon structure and organic compounds are adsorbed. See yellow marks in the figure above. The air flow also reduces the filter’s capacity. This is comparable, for example, to a battery which is connected to an appliance. The air flow rate (measured in m³/h) has a corresponding impact on the service life of the filter. The air flow rate is influenced mainly by the pressure drop of the filter, i.e. the carbon’s resistance to the air flow. Filters filled with granulated carbon (e.g., 4 x 8 mm) a resistance 1.4 times higher than filters filled with activated carbon in the form of pellets (4 mm). We offer filters that use filtering fabrics filled with carbon dust. While using this filter, the pressure drop is 2.5 times higher compared to filters filled with carbon pellets (4 mm). The following rule applies: The smaller the carbon particles, the greater the resistance to the air flow. The higher the resistance (pressure drop of the filter), the lower the air flow from the extraction fan. The pressure drop of the filter therefore is a factor contributing to the quality of the filter. Example: A 2-litre carbon filter filled with 4 x 8 mm carbon granulate is connected to a duct fan with an air flow rate of 160 m³/h. The effective air flow with the filter is approximately 100 m³/h. The same filter with activated carbon in the form of pellets (4 mm) achieves an air flow of 140 m³/h. A filter with carbon dust filled filtering fabric (curtain cloth) only reaches 70 m³/h. Therefore, it can be concluded that the service life of the carbon filter depends on the iodine uptake capacity and on the air flow rate in m³/h. If the air flow through the filter filled with pellets is reduced from 140 m³/h to 70 m³/h, the filter’s lifespan will double and the fan loading will decrease.

Adsorption quality

Activated carbon capacity is expressed by the iodine number in mg/g of carbon or by the CTC value. This value refers to the activity of carbon tetrachloride in activated carbon and is used in quality testing. The higher the CTC value, the more efficient the filter, because it is capable of absorbing more organic compounds. Basically: Increasing the duration of air flow through activated carbon (contact time) improves the adsorption result. The thickness of the carbon bed is therefore a decisive factor, but the pressure drop also increases according to the thickness of the carbon bed. It is therefore important to maintain a certain contact time between the air and the carbon. This means in practice: For pelletised carbon CTC70, an air flow of <200 m³/h per 1-1.5 kg of carbon is sufficient. The filtration result thus also depends on the air flow rate. If an odour appears, reduce the air flow! It also applies: the filtering efficiency increases with decreasing the temperature of the air.

Activated charcoal – granulated

Following activation, stone pine wood turned into activated charcoal is very light. Its bulk density is only approx. 200-250 g per litre of volume. Maximum CTC values of 50-55% can be achieved for granulated materials. The maximum iodine uptake usually reaches 500-950 mg/g. The reason for the relatively low values consists in the low specific weight of the raw material and the fact that wood cannot withstand high temperatures in the furnace for a long time. Coal becomes porous and crumbles. Advantages comprise favourable price, good availability and good initial adsorption characteristics. Disadvantages include sensitivity to moisture, a higher pressure drop, and a low adsorption force in proportion to volume, which impairs its service life.

Activated coconut shells

Activated coconut shells have very good adsorption characteristics and are used – among other things – for filtration of volatile gases, such as acetone, gasoline, etc. It is assumed that their high filtration performance owes to the natural fibrous structure of the shells. Activated coconut shells are also available in the form of pellets. They can reach iodine adsorption of up to 1250 mg/g, the maximum CTC value is 50-65%. The bulk density varies between 420 and 500 g/l depending on the activation time. Disadvantages include high price, shortage of raw material the supply of which depends on the harvest,

and the high pressure drop with granulated activated carbon.

Activated carbon in anthracite-based pellets

Anthracite, also known as black coal, has a very high carbon content and high specific gravity by nature. Unlike granulated coal, an additional production step is required for the production of pellets. Black coal is ground into powder and mixed with an adhesive (also called binder). Bitumen is commonly used for this purpose. The resulting material comprising coal and bitumen is extruded through a matrix with holes. Thanks to the binder, coal withstands high temperatures in the furnace longer than granulated coal. This makes it possible to achieve CTC values > 100% and iodine adsorption of 1280 mg/g. The advantages of this type of activated carbon consist in a low pressure drop and high iodine number / CTC value that can be achieved.

Additional advantages are the low pressure drop and very good service life even at high humidity. Disadvantages include a higher price and high emission values during the production.

Summary:

- Lightweight filters filled with activated charcoal (4 x 8 mash) rarely last longer than 3 months in practice, filters with a 10 cm thick bed last longer, however, their pressure drop is too high for standard duct fans.

- Textile filters filled with activated carbon dust (comparable to curtain fabric) are characterised by a very high pressure drop.

- The air flow is low, which prolongs the contact time. Thanks to a low air flow, these filters achieve a long service life. However, if higher air flow rates are to be achieved, high-pressure fans with high energy consumption are required. Increased air flow rate results in lower adsorption quality and shorter life of the filter. Its efficiency is then proportionately lower.

- Filters filled with activated carbon from coconut shells (4 x 8 mash) have very good filtration properties and long service life. However, they also have a high pressure drop.

- We at Primaklima use filters at our own facilities and know which of their properties are especially important. We fill our filters with anthracite in the form of CTC75 pellets or with coconut shell charcoal, i.e., with the highest quality activated carbon. Our activated carbon filters have a small pressure drop. They achieve high air flows which can be reduced if necessary. This results in long service life and the best adsorption. For our customers, this means: Simply the best! Iodine adsorption of a 2-litre activated carbon filter: 2 litres of carbon in the filter x 470 g/litre of bulk density = 940 g of carbon content in the filter.

Frequently Asked Questions

What is the acceptable air humidity level?

Air with humidity below 55% can be filtered very well by activated carbon filters. With air humidity of 60% or above, the filter’s performance decreases and good filter performance cannot be guaranteed if air humidity exceeds 70%.

What is an acceptable air flow range for my filter?

There is a general rule: The contact between air and activated carbon lasting from 0.05 to 0.2 s is sufficient for harmless odours and the filter achieves good results. Simply speaking, 1 kg of quality activated carbon, e.g., coconut shell carbon or 4 mm carbon pellets with the iodine adsorption capacity of 1150 mg/g and a bulk density of approx. 450 g/l, can ensure good air filtration at flow rates of 100-200 m³/h.

Are light filters better than heavy ones?

No, the more activated carbon (in kg) the filter, the better the adsorption result. The following rule applies: Adsorption capacity of the filter = weight of carbon in the filter in grams x iodine adsorption in mg per gram of carbon = iodine adsorption capacity of the filter.

How long does the activated carbon filter last?

This is difficult to say as the service life depends on various factors. If there is a lot of smoke in the room, the filter is exposed to extreme loads and its service life decreases significantly. If the filter is used in an environment with a lot of fine dust, e.g., close to a main road, its service life will be also impacted. Basically, the filter’s service life increases with cleaner air and lower air flows. You can extend the service life of your filter by using it only when you really need it (when the air smells). You can limit the air flow as this will exponentially prolong the service life of the filter.

I have a new filter and the air still smells!

This problem is usually caused by an overpressure in the room. Incorrect installation can also be the problem, e.g., when secondary air is drawn in. The solution is to reduce the air intake and to increase the air withdrawal through the filter. High humidity can also cause the filter to malfunction. The filter or the carbon can be dried for example with a heating fan. Once dried, activated carbon will work again.

The air discharged from the filter smells slightly!

This means that the contact time between air and carbon is too long. The solution is to reduce the fan output and slow down the air flow through the filter. You can also check the filter by spraying a perfume on a piece of fabric and assessing the scent of the discharged air in order to be able to adjust the air flow accordingly. It is also possible that the filter has reached the end of its service life and needs to be replaced.

Where and how should I install the filter?

Large activated carbon filters, which are very heavy, must be placed vertically in the room. Small filters can be mounted under the ceiling. It is important that the filter draws in warm air and discharges it to a cooler environment. In the opposite case, water would condense in the coal due to the dew point, the coal would get wet and would not filter.

There are black particles in the inner tube of my activated carbon filter!

This is caused by the manufacturing process and has no effect on the function. Simply remove the carbon particles.

There are black stains on the white filtering textile of my activated carbon filter!

The more the coal is activated, the more dust it contains. The dust sometimes penetrates into the prefilter fabric (for example due to its migration through the filter) and stains it black. Some manufacturers dye their textiles black to avoid this unsightly phenomenon. However, this has no effect on the filter’s function.

Can I add carbon to the filter myself?

This can be done, in principle, but activated carbon must be treated by vibration. The inner tube must be precisely centred. The flange neck must be pressed down with a suitable device. Primaklima offers original replacement carbon.

Whether the effort and the associated staining are worth the effort is for each user to decide.

Why is there almost no air coming out of my fan?

This is either due to a large pressure drop across the filter or the exhaust fan does not generate sufficient pressure. Primaklima fans and the corresponding filters are precisely tuned to work together. Primaklima uses only ebmpapst-Radical centrifugal fans, which are known for their high-pressure capability. In addition, this type of fans is by far the quietest and has a long service life.

Do you have any questions? Our primaklima team is here for you. Please send your questions to: support@primaklima.com

Deutsch

Deutsch